A love letter to concrete

In this piece, Tungsten Tang explores the history and background to our use of concrete in society, delving into the problems that have arisen and the future implications.

Dear concrete,

As divisive a figure you always are, I love you for your modest, honest and proudly standing contributions to us as humanity. For many sceptics, the love for you, concrete, has been alien, purely utilitarian and emotionally deficient. I must say otherwise — our love, as I will show in the rest of the letter, is full of humanism.

You have often been a symbol of political proclamation, empowerment and resilience. In economically torn post-WW2 Italy, the production capacity for steel was weak from the international sanctions placed during the fascist era. Engineers like Riccardo Morandi came up with the ingenious substitution of steel cables, required in abundance for suspension bridges with prestressed and reinforced concrete, to utilise the nation’s immense concrete production potential. The grey landscape dominated the Italian urban landscape as a symbol of national rejuvenation. Yet with the collapse of Ponte Morandi collapse in Genoa in 2018, there are again doubts about the integrity of many of these structures due to environmental factors like salty ocean breezes and fragile soil while revealing the hidden role mafias had in building these grand engineering structures — contributing to a lack of quality control.

Moving forward a decade and past the curtain, Soviet Premier Nikita Khrushchev’s speeches denouncing Stalinism praises concrete prefabricated panels (prefab) and industrialised buildings. Immediate rejection of the extravagance of Stalinist, neoclassical architecture (such as the Seven Sisters skyscrapers in Moscow), his proclamation carried through with the informal namesake Khrushchyovka — 5-storey mass residential houses built most commonly out of prefab. Admittedly a bit less idealised than what the Soviet leaders envisioned, it perhaps failed to keep up with the popular “socialist realist” aesthetics of day-to-day life built up during Stalin’s era. Yet indisputably, your legacy as an efficient solution to the housing crisis in the Eastern Bloc has remained.

Many times you have been wronged for crimes you did not commit. Growing up in Hong Kong, I often heard “concrete jungle” used as exasperation against stressful urban life. The association of you with prison-like architecture is not unfounded, but the bad urban planning is to be blamed for social segregation, not you.

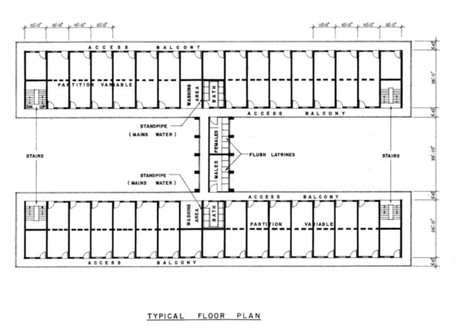

So much of our idea of you has been to build walls — yet with you we also build space. In our eager expansion upwards, we should not create properties to be bought and rented, but also communal space. The British colonial government might not have thought so when, following the 1959 Christmas night fire in the Shek Kip Mei squatter settlement, they decided to build the locally infamous 6-storey resettlement blocks in the most uncreative, standardised style — an H-shape with balcony-like corridors which all apartments exit towards, with conspicuously lacking communal kitchens and bathrooms where the corridors meet. The tradition of long corridors and steel gates persisted in Hong Kong’s concrete blocks until the last two decades, in public and private housing, in all variations of geometry and colour — from the circular stacks of Lai Tak Estate to the colourful walls of Choi Hung (lit. rainbow) Estate, both of which have recently attracted no shortage of local and foreign Instagrammers.

Nonetheless, our love comes at the cost of embodied CO2 (from 0.1 to 0.3 kg CO2 per kg concrete) amounting to 8% of the world’s CO2 emissions, and energy. To make cement, one of the three main ingredients of concrete alongside gravel and sand, limestone is burned to remove carbon, forming lime and CO2. This reaction is known as calcination, and is followed by subsequent reactions of lime with silicon oxide, aluminum oxide and ferric oxide to form cement. While calcination is the main culprit, the additional CO2 emissions of burning fossil fuels to heat up the kiln all add up to a significant amount of embodied CO2.

As much as our love subtends from when the Romans mixed volcanic ash with lime, it feels as if it’s new every day. Research led by Dr John Orr in the Department of Engineering, University of Cambridge, for example, investigates the replacement of steel reinforcement with knitted and wound string-like carbon fibre composites, and closely related fabric formwork for moulding. Aside from giving rise to more automated processes on and off-site in concrete fabrication, it also enables a greater variation in geometry which allows for a more uniform distribution of stress than in traditional rectangular concrete beams, where plenty of material is wasted carrying a small portion of the load.

Keeping up to pace with these novel structural methods, there is also the potential of reducing the environmental impact of cement production. While G7 leaders pledged to reduce carbon emissions of the steel and cement industries, there are hints that due to the large potential for established concrete structures to absorb atmospheric CO2, amounting to 43% of their original embodied CO2, the life cycle CO2 of concrete can possibly be made neutral, or even negative.

However, the cement industry is very reluctant to change for its pivotal role in building our cities. Nonetheless, efforts to replace the traditional “Portland cement” composition and production process are well underway. Often, they involve upcycling — using otherwise wasted materials for building, such as UCLA’s CO2NCRETE research in producing hydrated lime, a cement substitute, using only factory-emitted CO2, including those from cement plants. Similarly, Pulverised Fuel Ash (PFA, i.e. “fly ash”) from burnt coal can be used to substitute up to 40% of cement in concrete while maintaining an acceptable strength range of 20–55 MPa (megapascals), though the time required for such concrete to cure is also significantly longer than usual Portland cement-based ones — calling for the need of different construction methods. However, the method does not mitigate CO2 emissions in cement production, which are still costed towards coal combustion.

I am optimistic that we will see the more human side of you, concrete, with all the research and optimisation surrounding you, for many years to come. There will be a day when we part, and our love substituted by another material to a mass scale, and you remain a fond memory of the past. But for now, you’re all ours.

News / Cambridge academics stand out in King’s 2026 Honours List2 January 2026

News / Cambridge academics stand out in King’s 2026 Honours List2 January 2026 Interviews / You don’t need to peak at Cambridge, says Robin Harding31 December 2025

Interviews / You don’t need to peak at Cambridge, says Robin Harding31 December 2025 Comment / What happened to men at Cambridge?31 December 2025

Comment / What happened to men at Cambridge?31 December 2025 Features / “It’s a momentary expression of rage”: reforming democracy from Cambridge4 January 2026

Features / “It’s a momentary expression of rage”: reforming democracy from Cambridge4 January 2026 News / Varsity’s biggest stories of 202531 December 2025

News / Varsity’s biggest stories of 202531 December 2025